Reducing Maintenance Costs with Durable Magnetic Solutions

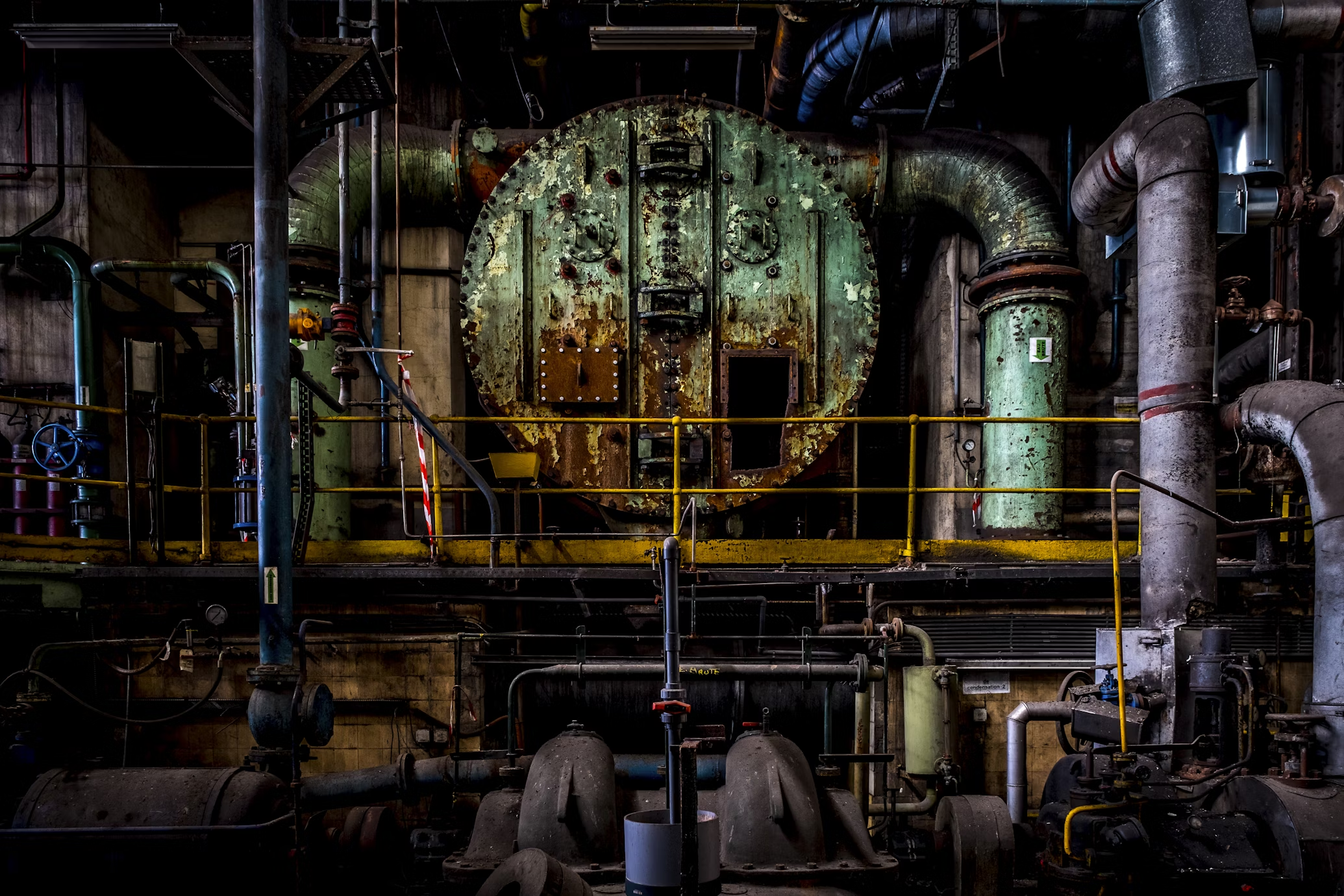

Importance of durability in industrial settings

The aim of industrial production is to reduce operational costs while maximizing production efficiency and profits. Equipment maintenance and replacement in high used shifted environments come with a substantial price tag. If an apparatus's components are consistently needing replacement it not only increases the cost of raw materials but also alters equipment performance owing to extended downtimes. Finding replacement solutions that are durable can go a long way in cutting costs but at the same time improving the efficiency of the company and its overall productivity. This engineering requirement rationally is the main incentive for the majority of companies out there.

Using permanent magnets in place of mechanical parts indeed result in a further cost reduction when we talk about operational maintenance since free and inexpensive permanent magnets are an epiphany in the world of industrial equipment. A cornerstone of industrial applications, effectively permanent magnets have large tolerances against damage and have significantly long life spans.

NdFeB Magnets

NdFeB Magnets are one of the most performant magnets existing today. Due to their high magnetic force and great durability, they have a wide application in various types of industrial equipment. NdFeB Magnetss have great resistance to demagnetization and corrosion, allowing them to be used in high stress, high temperature or corrosive environments, and after that their magnetic properties are still stable. Thus, the use of these permanent magnets would not only mitigate the chances of malfunction of the equipment but improve its overall life expectancy, thus decreasing the number of times maintenance and replacement would be requfred, and making a huge cut in long term operating costs also.

Installing new machinery can be expensive and prone to delay, and in time would cut into business profits, but with high quality NdFeB Magnets from manufacturers such as AIM Magnet, which offer permanent solutions, can help resolve maintenance and replacement issues.

Coating & Treatment

Treatment and coating of products is done where they are likely to serve for a longer period and wear and tear of the surface is to be reduced. For coating purposes, nickel, epoxy resin (Epoxy) and polytetrafluoroethylene (PTFE) can be used. Such magnet coatings assist in combating moisture, acids and some mechanical stresses thus ensuring corrosion does not take place. Particularly for magnets fit in devices that operate under or in harsh conditions, use of coatings that are wear and corrosion resistant will improve the operational life of the magnet while reducing maintenance seeking activities.

By and large, usage of nickel coatings will minimize oxidation corrosion and hence safeguard magnets from negative broadened environmental conditions, application of epoxy and PTFE coating will assist in chemically dipping the magnets without losing their strength. Coating magnets with these mentioned materials will ensure metal components hold their shape for long periods necessitating few replacements and not interrupting operations for long.

Practical benefits

Many industries truly do reap the rewards of having magnetic components as they are quite beneficial, with the first being the extended life span for these components which translates into the equipment as a whole lasting many years which in turn cuts down costs over time due to maintenance being needed less often. Second, because of the reliability and longevity of magnetic solutions, operational downtimes are also significantly minimized, which is very useful because it allows for the same as mentioned, cutting down costs and increasing productivity levels across the board. As a note, it's important to state that these benefits drive down costs and boost overall productivity in processes for respective industries that require constant operations. One such example could be the food processing industry.

Though, when looking for such areas, one would find the food processing industry claiming quite a few models of food plants, primarily food factories. Food is produced with the purpose of preventing various types of food impurities, such as metal debris, from entering the supply chain. In addition, great emphasis can also be placed on drop damages and lost production cost due to utilizing robust magnets by providing high working capacity as well as ensuring they are able to work in hostile working environments. In case such cost is being over the ability to use strong magnets, they are generally more economically justified for such equipment due to providing stability and minimizing damages.

Cooperation with reliable manufacturers

When selecting high-level magnetic solutions, one needs to consider the reliability of the manufacturer. Working with reputable manufacturers like our AIM Magnet gives you high quality magnet and magnet processing products as well as back up sales guarantees. This kind of manufacturers are statistically known to ensure that each and every manned production meets necessary quality standards for this enables them to be reliable in real use.

In addition, trusted manufacturers will also manufacture special coatings for use in different environmental conditions for the magnets to perform accordingly. For instance, equipment used in high temperature, high humidity and corrosive environments will require special coatings that enhance the anti-corrosion and anti-aging qualities of the magnets. For such issues, working with high-quality manufacturers is the only solution since they not only provide durable and consistent magnetic solutions but their after sales service supports the smooth running of equipment in terms of maintenance.

Our AIM Magnet has been a leading magnet supplier and magnets manufacturer worldwide for more than a decade and we strive to supply the best range of quality and durable yet affordable magnet solutions so as to aid in the reduction of the expenditure on regularly servicing equipment in different industries.