Customizable Shapes and Sizes of Permanent Magnets: What You Need to Know

Introduction: Why customization is essential in certain applications

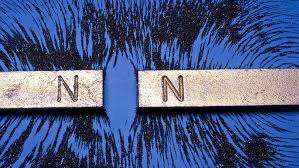

Along with the advance of modern science and technology, the whole industries have relied on the use of permanent magnets. For certain industries, for instance medical and aerospace, customized permanent magnets are of great importance. The consideration of permanent magnets in these fields is not only functional, but requires restrained and creative design intended at specific applications, as well as meeting greater performance and technical specifications.

Medical sector: For instance, permanent magnets in the magnetic resonance imaging (MRI) machines must be of high precision and stability as well as manged in small spaces.

Aerospace: The permanent magnet materials that are needed are to be designed in such a way that they have good physical properties and are as lightweight as possible. This is an advantage because it will enable satellites and other aircraft to operate in difficult environments while carrying more payload.

Benefits of Customization

Customizing the shape and size of permanent magnets increases the usefulness as well as increases the variety in the designs. This enables engineers to configure the system architecture better and give the users an enhanced experience. Customization can also assist in situations where standard components are unable to perform, for example, special mounting sites or non-standard connections.

Popular Shapes

Discs: Disc type of permanent magnets are commonly found in small-sized gadgets like buttons and sensors thanks to their compact size. They are great for precision instruments as they can generate a strong magnetic field strength in a confined space.

Blocks: Block type of permanent magnets can be used whenever a large amount of energy needs to be accumulated or utilized as building blocks. Due to their larger surface area,

these magnets are better utilized for making strong adsorbing devices or fixed parts in mechanical assemblies.

Rings: Ring type permanent magnets are used in the structure of motor and generator rotor. They are effective in making a rotating magnetic field that is uniform all over which enhances the efficiency of the motor and consumes less energy.

Arcs: Arc-shaped permanent magnets are utilized to meet the requirements of various electromagnetic configurations. This configuration also aids in directing the magnetic field, thus enhancing the energy efficiency of these devices and preventing avoidable waste of energy.

Customization Options

Cutting: Distinguished among advanced cutting techniques, AIM Magnet utilizes this technology to ensure that the necessary cutting of raw material is carried out which conforms to a size that the customer wants such that each product is suitable in the location it was meant to be placed.

Drilling: By providing pre-drilled holes, the assembly of permanent magnets with other joining components becomes easier and straightforward. This is necessary especially for products that are in need of rapid assembly.

Magnetizing: AIM Magnet also provides a magnetizing service which is dimensioned to cater for various application contexts, that is, the firm offers to apply a permanent magnetizing force on magnets according to the user’s specification on direction and strength. This procedure may assist in meeting particular functional objectives like magnetisation of multiple poles or intricate field imitation.

Applications Requiring Customization

Aerospace: Space missions' most crucial aspect is weight; with this in mind, AIM Magnet has permanent magnet solutions that do not exceed the required weight while maintaining a sufficient magnetic output for use in different space exploration attempts.

Electronic devices: There is a constant need to reduce the size and weight of electronic devices, which tend to become smaller and smaller. AIM Magnet manufactures custom made permanent magnets that easily create compact permanent magnets, which currently are the heart of several smart portable gadgets.

Art installations: We also see that artists increasingly try to integrate magnetism within their artworks. By collaborating with AIM Magnet, you can acquire customized permanent magnets of various attractive geometrical shapes that can help you achieve stunning art effects.

How to Work with Manufacturers

Good communication and cooperation is the key to developing customized permanent magnets. A customer can kick off a project with the submission of CAD files and relevant specific technical parameters and from there manufacturers are able to use the details to make prototypes and make multiple test trials till they are satisfied with what they have delivered. During the entire process, it is also one of the essential requirements of maintaining the product quality to ensure every production link complies with an international certification standard like RoHS or CE.