Exploring Magnetic Pull Force: Understanding the Strength of Magnets

Introduction

Magnets play a crucial role in various applications, from everyday household items to advanced technological devices. A key aspect of their functionality is the magnetic pull force, which determines how strong a magnet is. In this article, we'll explore what magnetic pull force is, how it is measured, and why it is important. We'll also discuss the factors affecting the pull force, practical applications of this magnetic property, and tips for choosing the right magnet based on pull force requirements.

What is Magnetic Pull Force?

Magnetic pull force refers to the maximum amount of force that a magnet can exert on a ferromagnetic material (such as iron) when the two are in direct contact. It essentially measures the magnet's strength and its ability to hold or lift objects. The stronger the magnetic pull force, the more powerful the magnet is.

How is Magnetic Pull Force Measured?

The pull force of a magnet is measured using a device called a pull force gauge. This tool measures the amount of force required to detach the magnet from a ferromagnetic surface. The reading is typically given in pounds (lb) or kilograms (kg). Accurate measurement of pull force is essential to ensure that the magnet will perform effectively in its intended application.

Steps to Measure Magnetic Pull Force:

- Preparation: Ensure that both the magnet and the ferromagnetic material are clean and free from any debris or dust, which can affect the measurement.

- Positioning: Place the magnet in direct contact with the ferromagnetic material to ensure maximum contact area.

- Using the Pull Force Gauge: Attach the pull force gauge to the magnet. Gradually pull the gauge until the magnet detaches from the material.

- Reading the Measurement: Note the reading on the pull force gauge, which indicates the maximum pull force of the magnet.

Using a Pull Force Tester for Professional Magnet Production

As a professional magnet manufacturer, it is crucial to ensure that each magnet meets the specified pull force requirements. This is achieved using a specialized instrument called a pull force tester. The pull force tester provides a detailed analysis of the magnet's strength by generating a comprehensive force curve, helping to identify the magnet's breakpoint. This breakpoint indicates the maximum force the magnet can withstand before detaching from the ferromagnetic material.

The pull force tester not only ensures that the magnets are up to standard but also aids in quality control, ensuring consistency across batches. By understanding the force curve, manufacturers can make necessary adjustments to the production process to enhance the magnetic performance.

Factors Affecting Magnetic Pull Force

Several factors influence the pull force of a magnet:

- Material Composition: The type of material the magnet is made from plays a significant role. Neodymium magnets, for example, are among the strongest permanent magnets available, thanks to their composition of neodymium, iron, and boron.

- Surface Area: The contact area between the magnet and the ferromagnetic material affects the pull force. A larger surface area results in a stronger pull force.

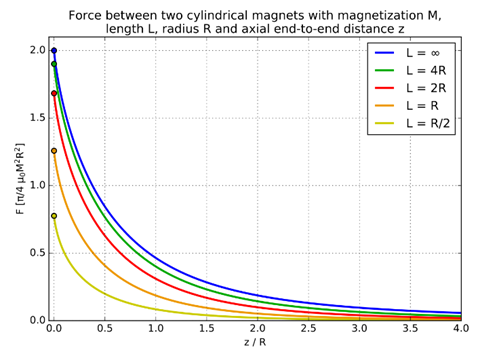

- Distance: The strength of the pull force decreases as the distance between the magnet and the object increases. This is due to the inverse square law of magnetism, which states that the magnetic force decreases with the square of the distance.

- Temperature: Magnets can lose their strength when exposed to high temperatures. For instance, neodymium magnets start to lose their magnetic properties at temperatures above 80°C (176°F).

- Coating and Surface Finish: The quality of the magnet's coating and the smoothness of the surface can impact the pull force. A smoother surface ensures better contact, thus increasing the pull force.

Magnetic Materials and Their Pull Forces

Different magnetic materials exhibit varying pull forces due to their unique compositions:

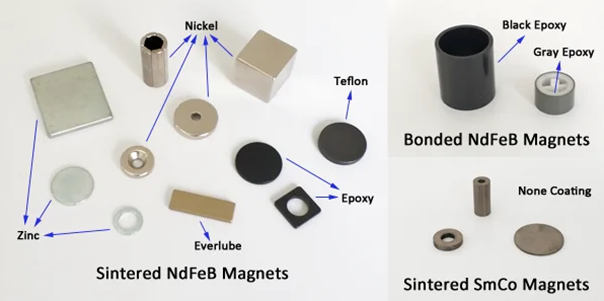

- Neodymium (NdFeB): Known for their exceptional strength, neodymium magnets have a high pull force, making them suitable for demanding applications such as motors, medical devices, and industrial machinery.

- Samarium Cobalt (SmCo): These magnets offer a strong pull force and are highly resistant to temperature fluctuations and corrosion. They are ideal for applications requiring stability under extreme conditions.

- Alnico: Alnico magnets, composed of aluminum, nickel, and cobalt, provide a moderate pull force and are often used in sensors, instruments, and loudspeakers.

- Ceramic (Ferrite): Ceramic magnets have a lower pull force compared to rare-earth magnets but are cost-effective and widely used in everyday applications like refrigerator magnets and magnetic clasps.

The Importance of Coatings for Magnets

Magnet coatings are crucial for enhancing the durability and performance of magnets. Common coatings include:

- Nickel (Ni-Cu-Ni): Nickel coatings are widely used for neodymium magnets. They provide excellent protection against corrosion and mechanical wear, ensuring the magnet's longevity.

- Zinc (Zn): Zinc coatings offer a cost-effective solution for protecting magnets from corrosion, especially in humid environments.

- Epoxy: Epoxy coatings provide a smooth finish and good resistance to moisture and chemicals, making them suitable for magnets used in harsh conditions.

- Gold (Au): Gold coatings, though expensive, offer superior corrosion resistance and are used in applications where the magnet must maintain a pristine appearance and performance.

Applications of Magnetic Pull Force

Understanding and measuring the pull force of magnets is crucial in various applications:

- Industrial Use: Magnets are used in heavy machinery for lifting and holding large metal objects. A strong pull force is essential to ensure safety and efficiency.

- Medical Equipment: In medical devices like MRI machines, powerful magnets are used, and their pull force must be precisely calibrated.

- Electronics: Magnets in speakers, hard drives, and other electronic devices require specific pull force characteristics to function correctly.

- Consumer Products: Everyday items like magnetic clasps, phone mounts, and fridge magnets rely on adequate pull force to perform their intended functions.

- Automotive Industry: Magnets are used in various automotive applications, including sensors, motors, and alternators. The pull force must be optimized to ensure the vehicle's components operate reliably.

- Renewable Energy: Wind turbines and other renewable energy technologies utilize strong magnets in their generators. The pull force is a critical factor in ensuring efficient energy conversion.

Tips for Choosing the Right Magnet Based on Pull Force

When selecting a magnet for a specific application, consider the following tips:

- Determine the Required Pull Force: Identify the amount of force needed for your application. This will help you select a magnet with the appropriate strength.

- Consider the Environment: Evaluate the operating conditions, including temperature, humidity, and exposure to chemicals. Choose a magnet with a suitable coating to ensure durability.

- Size and Shape: The size and shape of the magnet should align with the design requirements of your application. Ensure the magnet provides adequate surface area for optimal contact.

- Budget Constraints: While neodymium magnets offer the highest pull force, they can be expensive. Consider the cost-benefit ratio and explore alternative materials if budget constraints exist.

Conclusion

Magnetic pull force is a critical parameter that determines the effectiveness and application of a magnet. By understanding the factors that affect pull force and how to measure it accurately, one can select the right magnet for any specific application. Whether in industrial machinery, medical equipment, electronics, or everyday consumer products, the right magnet with the appropriate pull force ensures optimal performance and reliability.