Factors Influencing the Price of Neodymium Magnets

Neodymium magnets, a type of rare earth permanent magnet, are widely used in electronic devices, industrial manufacturing, and high-tech fields due to their superior magnetic properties. Despite the promising application prospects, the price of neodymium magnets fluctuates significantly, influenced by various factors. This article will delve into these influencing factors, including the price trends of neodymium, price comparisons of other rare earth elements, supply chain issues, demand fluctuations, production costs, trade policies, and explore the relationship between magnet prices and transportation costs.

Main Factors Affecting the Price of Neodymium Magnets

Neodymium Price Trends

The core component of neodymium magnets is neodymium (Nd), and its price volatility directly affects the cost of neodymium magnets. In recent years, the price of neodymium has undergone significant changes, mainly related to market supply and demand and geopolitical factors.

Historical Price Trends

- 2018-2019: Neodymium prices were relatively stable, with the market supply and demand being balanced. However, due to adjustments in China's environmental policies, neodymium supply was affected, causing slight price fluctuations.

- 2020: The COVID-19 pandemic disrupted global supply chains, limiting the production and transportation of neodymium, leading to a significant price increase in the second half of the year.

- 2021-2022: With the global economic recovery, the demand for electric vehicles and renewable energy technologies surged, further driving up neodymium prices.

- 2023: Neodymium prices stabilized, but due to continued high demand and tight supply, prices remained higher than pre-pandemic levels.

|

Year |

Price (USD/kg) |

|

2018 |

50 |

|

2019 |

55 |

|

2020 |

70 |

|

2021 |

90 |

|

2022 |

110 |

|

2023 |

105 |

Price Comparison of Other Rare Earth Elements

In addition to neodymium, other rare earth elements such as dysprosium (Dy), terbium (Tb), and samarium (Sm) are also commonly used in the production of permanent magnet materials, especially in high-temperature applications. The prices of these elements also impact the overall cost of neodymium magnets.

Rare Earth Element Price Comparison

|

Element |

Price (USD/kg) |

Typical Use |

|

Neodymium |

105 |

General-purpose magnets |

|

Dysprosium |

250 |

High-temperature magnets, NdFeB additives |

|

Terbium |

350 |

Enhancing high-temperature stability |

|

Samarium |

80 |

Samarium-cobalt magnets |

The high prices of dysprosium and terbium are due to their rarity and complex refining processes. These elements are often added to neodymium magnets to improve their performance at high temperatures, which is particularly important for electric vehicle motors and wind turbines.

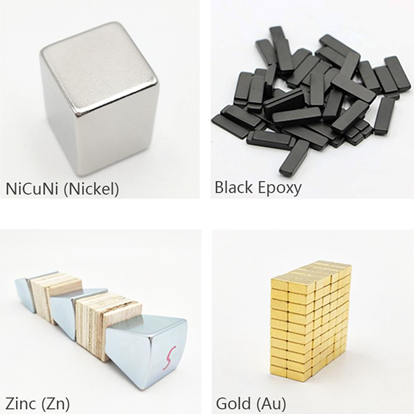

Coating Requirements for Magnets

Neodymium magnets usually require a coating to prevent oxidation and corrosion. Common coatings include:

- Zinc Plating: Economical and suitable for general applications.

- Nickel Plating: Offers good wear resistance and is widely used in industrial and consumer electronics.

- Epoxy Coating: Provides excellent corrosion resistance, ideal for harsh environments.

- Gold Plating: Used for special applications, offering superior corrosion protection and an attractive appearance.

Supply Chain Issues

The supply chain for neodymium is highly concentrated, with China being the major producer. Any disruption in Chinese production, whether due to environmental regulations, labor strikes, or geopolitical issues, can significantly impact global market prices. For example, China's recent tightening of environmental regulations on rare earth mines has led to supply constraints and price increases.

Demand Fluctuations

The demand for neodymium magnets is constantly increasing with emerging technologies, especially in electric vehicles and renewable energy systems. Any significant increase or decrease in these industries' activities can affect magnet prices. With the global shift towards green energy, the application of neodymium magnets in wind turbines and electric vehicles has expanded, leading to a sharp increase in demand and price volatility.

Production Costs

The production cost of neodymium magnets includes mining, refining, and manufacturing costs. Tightening environmental regulations, rising labor costs, and technological advancements can all impact production costs. For instance, China's stricter environmental requirements for rare earth mines have increased production costs, thereby driving up the price of neodymium magnets.

Relationship Between Magnet Prices and Transportation Costs

While the price of neodymium magnets is influenced by various factors, transportation costs are also an important consideration. This is particularly true for small-scale purchases, where transportation costs account for a large proportion of the total cost.

High Cost of Small-scale Purchases

For small-scale purchases, transportation costs are relatively high. The price of the magnets themselves may be low, but when purchased in small quantities, the transportation costs cannot be spread out, leading to a higher total cost per magnet. For example, purchasing a few kilograms of magnets may result in transportation costs accounting for more than 50% of the total cost, making small-scale purchases uneconomical.

Cost Advantage of Bulk Purchases

In contrast, bulk purchases can significantly reduce the transportation cost per magnet. Transportation fees can be spread out over a large number of magnets, reducing the unit cost. For instance, purchasing several tons of magnets may incur higher total transportation costs, but the cost per kilogram of magnets decreases significantly. This scale effect makes bulk purchases more cost-effective in terms of total cost.

Specific Analysis of Transportation Costs

Transportation costs include not only shipping fees but also packaging, insurance, and tariffs. The following is a specific analysis of transportation costs:

- Shipping Fees: Primarily depend on the transportation distance and mode. Air freight is expensive but fast; sea freight is cheaper but slower.

- Packaging: Magnets require special packaging to prevent damage during transportation. High-quality packaging materials and techniques increase costs.

- Insurance: Purchasing transportation insurance is necessary to avoid risks during transit. This part of the cost also affects the total cost.

- Tariffs: Different countries impose different tariffs on magnet imports, which also affect the total cost.

Strategies to Optimize Transportation Costs

To optimize transportation costs, the following strategies can be adopted:

- Choose the Appropriate Mode of Transportation: Depending on the purchase volume and time requirements, select the appropriate mode of transportation. Bulk purchases can choose sea freight to save costs.

- Optimize Packaging Solutions: Use suitable packaging materials and techniques to protect the magnets while saving packaging costs.

- Purchase Transportation Insurance: Select the appropriate insurance plan based on the value of the goods and risk assessment to reduce risk costs.

- Understand Tariff Policies: Understand and plan the tariff policies of the destination country in advance, reasonably arrange transportation and customs clearance processes, and reduce unnecessary costs.

Trade Policies

Tariffs, export quotas, and trade agreements can impact the cost and availability of neodymium magnets. For instance, trade tensions between major economies can lead to supply chain disruptions and price increases.

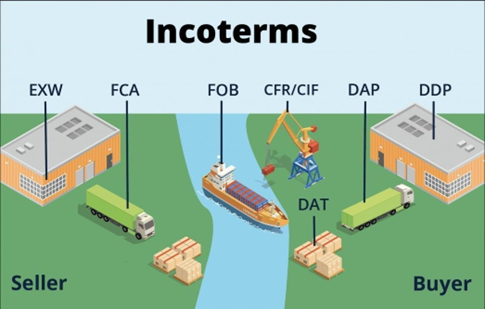

Incoterms (International Commercial Terms)

- FOB (Free on Board): The seller is responsible for delivering the goods to the nearest port. The buyer takes over responsibilities and costs once the goods are on board.

- CIF (Cost, Insurance, and Freight): The seller covers the cost of goods, insurance, and freight to the destination port. The buyer is responsible for customs clearance and other costs after the goods arrive.

- EXW (Ex Works): The buyer takes full responsibility for transportation and costs from the seller's premises.

Payment Terms

- T/T (Telegraphic Transfer): Payment is made via bank transfer, often with an advance deposit and the balance paid before shipment.

- L/C (Letter of Credit): A bank guarantees the buyer's payment to the seller, providing security for both parties.

Quality and Compliance

- ROHS (Restriction of Hazardous Substances): Ensures that magnets meet environmental and safety standards.

- ISO 9001: Certification that ensures the manufacturing process meets international quality management standards.

Conclusion

The price of neodymium magnets is influenced by various factors, including the price of neodymium, other rare earth elements, supply chain issues, demand fluctuations, production costs, and trade policies. Although these factors cause significant price fluctuations, businesses can effectively reduce total costs through reasonable procurement strategies and transportation cost optimization, achieving maximum economic benefits.