Understanding NdFeB Grades: A Comprehensive Guide to Neodymium Magnets

Neodymium magnets, also known as NdFeB magnets, are the strongest type of permanent magnets available commercially. These magnets are composed of neodymium, iron, and boron (Nd2Fe14B). Their unique composition provides them with remarkable magnetic properties, making them essential in various applications, from industrial machinery to everyday consumer electronics. This article delves into the different grades of NdFeB magnets, explaining their characteristics, applications, and how to select the right grade for your project.

What Are NdFeB Grades?

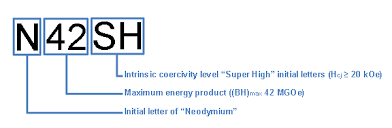

NdFeB magnets are categorized into different grades based on their magnetic strength and thermal stability. These grades are indicated by a series of letters and numbers, which provide detailed information about the magnet's performance. The grade of an NdFeB magnet typically includes a number, indicating its maximum energy product, and one or two letters denoting its intrinsic coercivity and temperature stability.

Maximum Energy Product (BHmax)

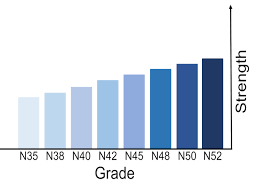

The maximum energy product, measured in MegaGauss-Oersteds (MGOe), is a key indicator of a magnet's strength. It represents the density of magnetic energy stored in the magnet. Higher values indicate stronger magnets. NdFeB magnets are available in grades ranging from 35 MGOe to over 52 MGOe. Common grades include N25-N52, and N52 being the strongest.

N35: Indicates a maximum energy product of 35 MGOe.

N38: Indicates a maximum energy product of 38 MGOe.

N42: Indicates a maximum energy product of 42 MGOe.

N48: Indicates a maximum energy product of 48 MGOe.

N50: Indicates a maximum energy product of 50 MGOe.

N52: Indicates a maximum energy product of 52 MGOe.

Intrinsic Coercivity (Hci)

Intrinsic coercivity measures a magnet's resistance to demagnetization. This property is crucial in applications where magnets are exposed to high temperatures or external magnetic fields. NdFeB magnets with high intrinsic coercivity are designated with letters such as M, H, SH, UH, EH, and TH, in increasing order of their thermal resistance. For instance:

N35: Standard grade with no special temperature rating.

N35H: High intrinsic coercivity, suitable for higher temperatures.

N35SH: Super-high intrinsic coercivity, suitable for even higher temperatures.

Temperature Stability

The temperature stability of NdFeB magnets is vital in determining their performance in various environments. Standard NdFeB magnets can typically operate up to 80°C, but special grades are designed to withstand higher temperatures. The letters H, SH, UH, EH, and TH also indicate their maximum operating temperatures:

H: Up to 120°C

SH: Up to 150°C

UH: Up to 180°C

EH: Up to 200°C

TH: Up to 230°C

Coatings for NdFeB Magnets

Due to the high iron content in NdFeB magnets, they are prone to corrosion. To protect against this, various coatings are applied to enhance their durability and longevity. Common coatings include:

Nickel-Copper-Nickel (Ni-Cu-Ni): This is the most common coating, providing good resistance to corrosion and wear. It gives the magnet a shiny, silver appearance.

Zinc (Zn): Offers moderate corrosion resistance and is typically used in applications where the magnet will not be exposed to harsh environments.

Epoxy: Provides excellent corrosion resistance and is available in different colors, offering an additional layer of protection for magnets used in outdoor or harsh environments.

Gold (Au): Provides superior corrosion resistance and is used in specialized applications where both high performance and aesthetic appeal are required.

Tin (Sn): Often used for medical applications due to its excellent corrosion resistance and biocompatibility.

Parylene: A thin, conformal coating that offers excellent corrosion resistance and is often used in high-precision applications.

Selecting the Right Grade for Your Application

Choosing the appropriate NdFeB grade depends on the specific requirements of your application. Here are some key factors to consider:

Magnetic Strength: For applications requiring maximum magnetic force, such as motors and generators, high-grade magnets like N52 are ideal.

Temperature Resistance: For environments with high temperatures, select magnets with high intrinsic coercivity, such as N48SH or N45UH.

Size and Weight: Higher-grade magnets can provide stronger magnetic fields in smaller sizes, which is crucial for compact devices like smartphones and medical equipment.

Cost: Higher grades and special temperature-resistant magnets are more expensive. Balancing performance needs with budget constraints is essential.

Coating Requirements: Consider the environment in which the magnet will be used and choose a coating that provides adequate protection against corrosion and wear.

Common Applications of Different NdFeB Grades

NdFeB magnets are used across various industries due to their versatility. Here are some common applications:

Electronics: Smartphones, headphones, and hard drives often use high-grade magnets like N48 and N52 for compact, powerful magnetic fields.

Medical Devices: MRI machines and medical instruments require precise, reliable magnets with high coercivity, such as N45UH.

Automotive: Electric vehicles and hybrid cars use NdFeB magnets in motors and sensors. N42SH and N48SH are popular choices due to their strength and temperature stability.

Industrial Machinery: Robotics and automation systems benefit from high-performance magnets like N50 and N52 for efficient operation.

Renewable Energy: Wind turbines and other renewable energy sources use NdFeB magnets in generators. N42 and N48 are commonly used grades.

Conclusion

NdFeB magnets offer unparalleled magnetic strength and versatility, making them indispensable in modern technology. Understanding the different grades of NdFeB magnets is crucial for selecting the right magnet for your application. By considering factors like magnetic strength, temperature resistance, and specific application requirements, you can ensure optimal performance and longevity of your magnetic components.

For more information on NdFeB magnets and to find the right grade for your needs, contact UCMD. We specialize in providing high-quality magnetic products and solutions tailored to your specific requirements