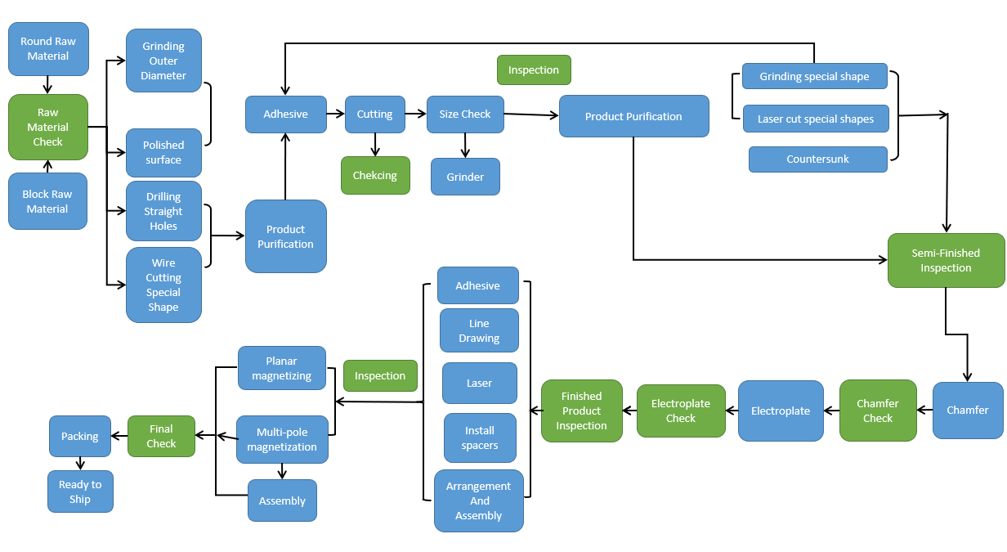

Steps Of Producing Magnet

Neodymium-iron-boron (NdFeB) permanent magnet materials are rapidly developing and widely cited due to their properties, abundant raw materials, and low prices. Mainly used in electro-acoustic devices, the instrument industry, the automobile industry, the petrochemical industry, nuclear magnetic resonance, magnetic therapy, and health care. It uses a wide range of pictures and is closely connected with our daily lives.

NdFeB is popularly called magnet (some people call it magnetite). It is a kind of magnetic material that does not cut magnetism at room temperature, so it is also called magnet. It mainly produces processes: Ingredient---smelting---powdermaking---profiling---sintering&tempering---magnetic test---grinding---cutting---electroplating---finished product.

Sticking material is to make the material that is brought down according to a certain shape, and stick it together with 502 glue for easy processing.

The next step is cutting: the cutting is done by our inner circle slicer. The rough materials processed by AIM Powerful Magnets can be roughly divided into three types:

1) A cylindrical shape: the diameter is 2 mm to 100 mm, and the thickness is more than 0.5 mm(depending on diameter size). It can be processed, and the round magnet can be processed more conveniently. It can be cut at one time. Therefore, the round magnet is often used when making an order. The advantages of a large magnet are fast processing speed and short delivery time.

2) square magnets: The processing of square magnets is slower because it needs to be cut on all six sides. A product needs to be processed three times to be successful. Compared with round magnets, there are two more processes, and the bonding workshop is not as cylindrical. Good adhesion. Therefore, the processing speed of the square magnet is slow, and the need longer production time than round magnet.

3) Perforated products: Before the product is processed, a prescribed hole is punched in the blank in advance and then processed. The square needs to be processed to a certain degree of smoothness, then punching, and then cutting, which is more troublesome. Perforated products are also widely cited in the market, and the prospects are also very optimistic. At the same time, our factory can also process some special-shaped products, such as trapezoidal, large and small hollow magnets.

Unplated magnet inspection is the qualification inspection of the semi-finished products processed by the slicing workshop. Generally, the thickness of the disc without special requirements is ±0.05mm and the square is ±0.1mm.

Receipt material is to check the quantity of the product in advance, so as to find out the quantity of shipment immediately

Polishing (also called chamfering) is the first process of electroplating. It is to grind the corners around the product to a certain degree according to customer requirements to make the surface smoother to improve the appearance quality of the product.

Electroplating is an important process for product appearance and storage time. Its surface treatment mainly includes zinc, nickel, copper, chromium, gold, black zinc, and epoxy resin. The surface plating is not the same, its color is also different, and its storage time is also different. Each has its advantages and disadvantages.

The last step is magnetizing & packing. The magnetization principle: First charge the capacitor with a DC high-voltage voltage, and then discharge it through a coil with very small resistance. The peak discharge pulse current can reach tens of thousands of amperes. This current pulse generates a strong magnetic field in the coil, which permanently magnetizes the hard magnetic material placed in the coil.

Magnetic device assembly: According to the needs of customers, engineers will design assembly fixtures, formulate a combination plan, and combine magnets with hardware and plastic parts into magnetic devices