Magnetiese trekkrag ondersoek: Die krag van magnete verstaan

Inleiding

Magnete speel 'n belangrike rol in verskeie toepassings, van alledaagse huishoudelike artikels tot gevorderde tegnologiese toestelle. 'n Belangrike aspek van hulle funksionaliteit is die magnetiese trekkrag, wat bepaal hoe sterk 'n magneet is. In hierdie artikel sal ons ondersoek wat magnetiese trekkrag is, hoe dit gemeet word en waarom dit belangrik is. Ons sal ook bespreek watter faktore die trekkrag beïnvloed, hoe hierdie magnetiese eienskap prakties toegepas kan word en wenke vir die keuse van die regte magneet wat op die trekkragvereistes gebaseer is.

Wat is magnetiese trekkrag?

Magnetiese trekkrag verwys na die maksimum hoeveelheid krag wat 'n magneet op 'n ferromagnetiese materiaal (soos yster) kan uitoefen wanneer die twee in direkte kontak is. Dit meet basies die magneet se sterkte en sy vermoë om voorwerpe vas te hou of op te lig. Hoe sterker die magnetiese trekkrag, hoe kragtiger is die magneet.

Hoe word magnetiese trekkrag gemeet?

Die trekkrag van 'n magneet word gemeet met behulp van 'n toestel wat 'n trekkragmeter genoem word. Hierdie instrument meet die hoeveelheid krag wat nodig is om die magneet van 'n ferromagnetiese oppervlak af te skei. Die telling word gewoonlik in pond (lb) of kilogram (kg) gegee. Om te verseker dat die magneet doeltreffend sal werk wanneer dit gebruik word, is dit noodsaaklik om die trekkrag akkuraat te meet.

Stappe om magnetiese trekkrag te meet:

- Voorbereiding : Maak seker dat beide die magneet en die ferromagnetiese materiaal skoon is en vry is van enige puin of stof wat die meting kan beïnvloed.

- Posisionering : Plaas die magneet in direkte kontak met die ferromagnetiese materiaal om maksimum kontakarea te verseker.

- Die gebruik van die trekkragmeter : Sluit die trekkragaanwyser aan die magneet. Trek die meter geleidelik totdat die magneet van die materiaal loskom.

- Die meting lees : Let op die telling op die trekkragmeter, wat die maksimum trekkrag van die magneet aandui.

Gebruik 'n trekkragtoetser vir professionele magneetproduksie

As 'n professionele magneetvervaardiger is dit noodsaaklik om te verseker dat elke magneet aan die spesifieke trekkragvereistes voldoen. Dit word bereik met behulp van 'n gespesialiseerde instrument wat 'n trekkragtoetser genoem word. Die trekkragtoetser verskaf 'n gedetailleerde analise van die magneet se sterkte deur 'n omvattende kragkurwe te genereer, wat help om die breekpunt van die magneet te identifiseer. Hierdie breekpunt dui op die maksimum krag wat die magneet kan weerstaan voordat dit van die ferromagnetiese materiaal losbreek.

Die trekkragtoetser verseker nie net dat die magnete aan die standaard voldoen nie, maar help ook met kwaliteitsbeheer en verseker dat die stelle konsekwent is. Deur die kraggreef te verstaan, kan vervaardigers die nodige aanpassings aan die produksieproses maak om die magnetiese prestasie te verbeter.

Faktore wat die magnetiese trekkrag beïnvloed

Verskeie faktore beïnvloed die trekkrag van 'n magneet:

- Materiaal samestelling : Die soort materiaal waaruit die magneet gemaak is, speel 'n belangrike rol. Neodymiummagnete is byvoorbeeld van die sterkste permanente magnete wat beskikbaar is, want hulle bestaan uit neodymium, yster en boor.

- Oppervlakte : Die kontakarea tussen die magneet en die ferromagnetiese materiaal beïnvloed die trekkrag. 'n Groter oppervlak lei tot 'n sterker trekkrag.

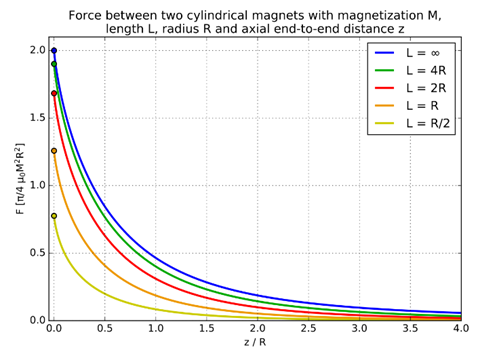

- Afstand : Die krag van die trekkrag neem af namate die afstand tussen die magneet en die voorwerp toeneem. Dit is te wyte aan die omgekeerde vierkantwet van magnetisme, wat sê dat die magnetiese krag afneem met die vierkant van die afstand.

- Temperatuur : Magnete kan hulle sterkte verloor wanneer hulle aan hoë temperature blootgestel word. Byvoorbeeld, neodymimagneet begin om hul magnetiese eienskappe te verloor by temperature bo 80 °C (176 °F).

- Bekleding en oppervlakbewerking : Die kwaliteit van die magneet se laag en die gladheid van die oppervlak kan die trekkrag beïnvloed. 'n Gladder oppervlak verseker beter kontak en verhoog sodoende die trekkrag.

Magnetiese materiale en hulle trekkragte

Verskillende magnetiese materiale vertoon verskillende trekkragte as gevolg van hulle unieke samestellings:

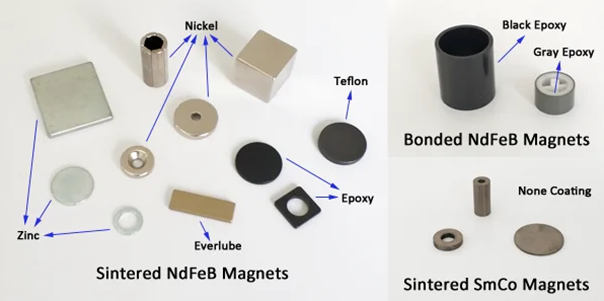

- Neodymium (NdFeB) : Neodymiummagnete is bekend vir hulle uitsonderlike sterkte en het 'n hoë trekkrag, wat hulle geskik maak vir veeleisende toepassings soos motors, mediese toestelle en industriële masjinerie.

- Samarium Kobalt (SmCo) : Hierdie magnete het 'n sterk trekkrag en is baie bestand teen temperatuurskommelings en korrosie. Hulle is ideaal vir toepassings wat stabiliteit onder uiterste toestande vereis.

- Alnico : Alni-magnete, wat uit aluminium, nikkel en kobalt bestaan, voorsien 'n matige trekkrag en word dikwels in sensors, instrumente en luidsprekers gebruik.

- Keramiek (ferriet) : Keramiekmagnete het 'n laer trekkrag in vergelyking met seldsame aardmagnete, maar is koste-effektief en word wyd gebruik in alledaagse toepassings soos yskasmagnete en magnetiese sluite.

Die belangrikheid van bedekkings vir magnete

Magneetbedekkings is noodsaaklik om die duursaamheid en prestasie van magnete te verbeter. Algemene coatings sluit in:

- Nikkel (Ni-Cu-Ni) : Nikkelbedekkings word wyd gebruik vir neodymimagneet. Hulle bied uitstekende beskerming teen korrosie en meganiese slijtage, wat die magneet se lang lewe verseker.

- Sink (Zn) : Sinkbedekkings bied 'n koste-effektiewe oplossing om magnete teen korrosie te beskerm, veral in vogtige omgewings.

- Epoksie : Eposlaag bevat 'n gladde afwerking en is goed bestand teen vog en chemikalieë, wat dit geskik maak vir magnete wat in moeilike toestande gebruik word.

- Goud (Au) : Goudbedekkings, hoewel duur, bied 'n beter korrosiebestandheid en word gebruik in toepassings waar die magneet 'n ongeskonde voorkoms en prestasie moet behou.

Toepassings van magnetiese trekkrag

Die begrip en meting van die trekkrag van magnete is van kardinale belang in verskeie toepassings:

- Industriële Gebruik : Magnete word in swaar masjinerie gebruik om groot metaalvoorwerpe op te lig en vas te hou. 'n Sterk trekkrag is noodsaaklik om veiligheid en doeltreffendheid te verseker.

- Mediese Toerusting : In mediese toestelle soos MRI-masjiene word kragtige magnete gebruik, en hulle trekkrag moet presies gekalibreer word.

- Elektronika : Magnete in luidsprekers, hardeskywe en ander elektroniese toestelle vereis spesifieke trekkragkenmerke om behoorlik te kan funksioneer.

- Verbruikersprodukte : Alledaagse items soos magnetiese sluiters, telefoonhouer en yskasmagnete is afhanklik van voldoende trekkrag om hulle beoogde funksies te verrig.

- Motorbedryf : Magnete word in verskeie motortoepassings gebruik, insluitende sensors, motors en kragopwekkers. Die trekkrag moet geoptimaliseer word om te verseker dat die voertuig se komponente betroubaar werk.

- Hernubare Energie : Windturbines en ander hernubare energie-tegnologieë gebruik sterk magnete in hulle kragopwekkers. Die trekkrag is 'n kritieke faktor om doeltreffende energieomskakeling te verseker.

Wenke om die regte magneet te kies op grond van trekkrag

Wanneer jy 'n magneet vir 'n spesifieke toepassing kies, moet jy die volgende wenke oorweeg:

- Bepaal die vereiste trekkrag : Identifiseer die hoeveelheid krag wat nodig is vir jou aansoek. Dit sal jou help om 'n magneet met die regte sterkte te kies.

- Dink aan die omgewing : Beoordeel die bedryfsomstandighede, insluitende temperatuur, humiditeit en blootstelling aan chemikalieë. Kies 'n magneet met 'n geskikte laag om duursaamheid te verseker.

- Grootte en Vorm : Die grootte en vorm van die magneet moet ooreenstem met die ontwerpvereistes van jou toepassing. Maak seker dat die magneet voldoende oppervlak bied vir optimale kontak.

- Begrotingsknoppe : Hoewel neodymimagneet die grootste trekkrag bied, kan dit duur wees. Oorweeg die koste-voordeelverhouding en ondersoek alternatiewe materiale as daar begrotingsbeperkings is.

Gevolgtrekking

Magnetiese trekkrag is 'n kritieke parameter wat die doeltreffendheid en toepassing van 'n magneet bepaal. Deur die faktore te verstaan wat die trekkrag beïnvloed en hoe om dit akkuraat te meet, kan 'n mens die regte magneet vir enige spesifieke toepassing kies. Hetsy in industriële masjinerie, mediese toerusting, elektronika of alledaagse verbruikersprodukte, die regte magneet met die toepaslike trekkrag verseker optimale prestasie en betroubaarheid.